CDs and DVDs can be reliable for many decades with proper handling. As with all other types of media, degradation is inevitable over time, but steps can be taken to help prevent it from occurring prematurely. This section covers the effects of environmental conditions and physical handling on optical discs.

5.1 Environmental Conditions

5.1.1 Temperature and Relative Humidity

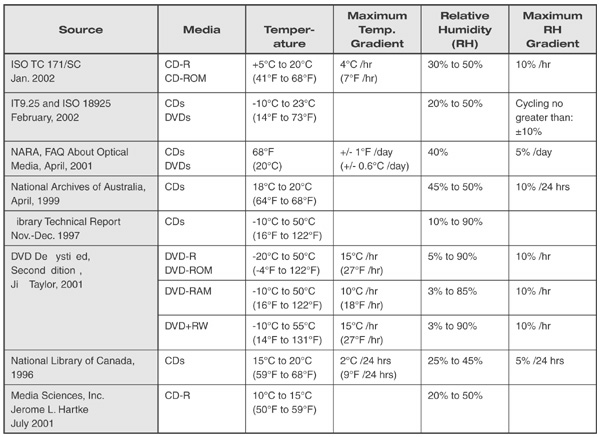

Optical discs will perform well within a wide range of temperature and relative humidity conditions. Discs kept in a cooler, less-humid environment and not subjected to extreme environmental changes should last longer. Optical discs stored in an optimal environment will outlast discs that are not. Storage temperature and relative humidity ranges recommended in various technical sources are presented in Table 3.

Table 3: Recommended storage parameters from different sources

If stored at a very low temperature relative to the user environment, the disc should be gradually acclimated to the environment in which it will be used to reduce stress and moisture condensation. A significant, abrupt temperature change will cause greater stress than a gradual change. Leaving the disc in its packaging will allow gradual acclimation to a changed environment. Discs used frequently should be stored at a temperature similar to that of the environment in which they are to be used. This minimizes stress from frequent temperature changes.

Given the absence to date of relevant testing, the precise effects of storing CDs and DVDs in freezing temperatures are not yet known. Freezing and thawing may create harmful stresses in the disc because of differing expansion rates of the layers, but it is unclear how much this stress might affect the disc. There may even be a benefit to uninterrupted freezing of a disc for an extended period. Until testing is done to measure the effects of freeze-thaw cycles or long-term freezing, the benefits or harmful effects will remain uncertain.

5.1.2 Light Exposure

Effect of Light on ROM Discs

Although the effect of light on ROM discs over time is not known, the effects of long-term exposure to light (e.g., UV, infrared, fluorescent) under ambient intensity, such as room lighting, are generally thought to be so minimal that light is not considered a factor in the lifetime of the ROM disc. Any effect of light on the disc would involve degradation of the polycarbonate substrate (plastic) and would become noticeable only after several decades of exposure to daily storage facility lighting or sunlight through windows. Degradation effects would likely be in the form of “clouding” or “coloring” of the polycarbonate. To our knowledge, there is no report on the potential impact of this kind of material change on the playability of the disc. Light effects on ROM discs, therefore, are considered negligible.

Effect of Light on R Discs

Prolonged exposure to sunlight or other sources of UV light can significantly increase the degradation rate of the dye (recordable) layer in R discs. Deterioration of the dye makes it less transparent. As a result, some, or all, of the unmarked areas in the dye could be read as marks, depending on the severity of degradation. These areas will then result in errors when read by the laser.

| Direct sunlight to R discs is harmful for two reasons: |

|---|

|

The most likely cause of damage to R discs from direct sunlight is by heat buildup in the disc affecting the dye. Much of the ultraviolet range of sunlight can be filtered (or absorbed) by glass-e.g., the glass of a window. However, the lower light frequency (infrared) range will pass through a window and generate heat in the disc. A disc in a case, or one with a dark label, printing, or color that allows it to absorb more sunlight, also makes a disc more prone to heat buildup from direct sunlight exposure. The effects of heat buildup can be minimized if the disc is kept cool, such as in an air-conditioned room. Exposure to direct sunlight without protection (glass or plastic window) will cause the disc dye to degrade more rapidly. These observations on the effects of light are based on preliminary tests conducted at NIST.

Effect of Light on CD-RW and DVD-RW, DVD+RW, and DVD-RAM Discs

Light should have minimal, if any, effect on RW and RAM discs, for the phase-changing film used in such discs is not light sensitive. This film, however, is affected by heat; in fact, it is heat generated from the intense laser beam that writes data in the phase-changing film. Heat buildup in RW or RAM discs caused by direct sunlight will accelerate the degradation rate of the phase-changing film just as it does that of the dye in R discs. The phase-changing film in RW and RAM discs degrades naturally, and from heat buildup by direct sunlight, at a faster rate than the dye in R discs.

| CD-R, CD-RW, DVD-R, DVD+R, DVD-RW. DVD+RW, and DVD-RAM discs can become unusable in a matter of days. If such a disc is left in an environment that allows direct sunlight and extreme heat buildup (e.g., on the dashboard of a car in summertime, or next to a heater by a window), the organic dye or phase-changing film that holds the data will degrade quickly, causing the disc to become unreadable. A disc is not protected from the effects of heat buildup if left in a case that is exposed to direct sunlight or other sources of heat. Extreme heat buildup can also cause warping of the disc. |

5.1.3 Moisture

The polycarbonate substrate, or the plastic composition, that makes up most of the disc is a polymer material that is vulnerable to moisture. Any prolonged exposure to moisture resulting from a spill, humid air, or immersion allows water to become absorbed into the disc, where it may react with any of the layers. Returning the disc to a dry environment will allow the absorbed moisture or water to dissipate out of the disc over time; however, water or a water-based liquid may leave behind, within the disc, contaminants such as dyes or other dissolved minerals. If the disc has experienced no permanent damage from absorption of the liquid, it should play normally. In NIST tests, a CD totally submerged in clean water for 24 hours was found to be unreadable initially after removal and surface drying. It played normally, however, after 24 hours of drying out at approximately 70¡F and 50% relative humidity (normal room conditions).

5.1.4 Organic Solvents

Contact of the disc with strong organic solvents must be avoided. Harsher solvents such as acetone or benzene will dissolve the polycarbonate and thereby damage the disc beyond repair. Limited contact (cleaning) with mild solvents such as isopropyl alcohol or methanol is permitted, as these solvents evaporate quickly and will not dissolve the polycarbonate. They may, however, dissolve or damage labels or optional coatings on the label side of the disc.

5.1.5 Magnetism, X-rays, Microwaves, and Radiation

The effects on optical discs of magnetism, X-rays, microwaves, and radiation can be summarized as follows:

- Magnetism should have no affect on CDs or DVDs.

- X-ray exposure (e.g., from airport detectors) will not harm optical discs.

- Microwaves in a microwave oven will destroy a disc. (It may also destroy your microwave oven because of the metal in the disc.)

- Information on the effects of radiation is currently available from testing done in connection with the U.S. Postal Service’s irradiation of mail to counter bioterrorism threats. CDs and DVDs have been tested at exposure levels of 60 to 300 kilogreys of radiation. According to the results, disc data were unaffected by the radiation; the packaging and discs themselves, however, showed some discoloration and had a burnt-substance odor. There were no traces of residual radiation on any of the packages or discs (High-Tech Productions, no date). A quantitative summary of these effects is also available from Jerome L. Hartke, of Media Sciences, Inc.

5.1.6 Individual Disc Storage

Optical discs should be kept in individual storage containers until used and returned to those containers immediately thereafter. Typical storage containers, as listed below, isolate and help protect discs from airborne contaminants and other foreign material. They also help buffer rapid environmental changes that can cause stresses to the disc. Cases are designed to keep surfaces of the disc from contact with the inside of the case. Only one disc should be placed on the hub (or each hub) in the case. To remove the disc, one should press down on the hub tab while holding the outer edge of the disc with the fingers and then lift up. Bending the disc while lifting it off the hub tab should be avoided.

For long-term disc storage, it may sometimes be prudent to remove the label insert or booklet from inside the case and attach it to the outside, perhaps in a sleeve. In theory, the paper can attract moisture and produce higher moisture content in the case. The paper may also spread moisture by contact with the disc. This recommendation is based on no specific tests of the effects of paper inside a case; it is merely a consideration–one that takes on added significance with large amounts of paper inside a disc case and higher-than-recommended humidity conditions.

Cases commonly used for individual disc protection include the following:

- Jewel case. The jewel case, which comes in different varieties, holds one to six discs, depending on its design. It is typically a transparent plastic case with a hinged lid, one or more plastic trays, an inlay card for labeling, and an optional booklet.

- Slimline case. As its name suggests, a slimline case is a slimmer version of the jewel case but without the tray. It comes with an inlay card (J-card) and is primarily used for audio discs.

- Amaray case. An amaray case is a plastic case used for commercially available prerecorded (replicated) DVD videos and games.

- Snapper case. An alternative to the amaray case, the snapper case is a plastic DVD case with a cardboard cover that is snapped shut and held in place by a plastic lip.

5.2 Surface-Handling Effects

Anything on an optical disc surface that impedes the ability of the laser to focus on the data layer can result in missing data as the disc is being read. Fingerprints, smudges, scratches, dirt, dust, solvents, moisture, and any other foreign material can interfere with the ability of the laser to read the data. They can also interfere with the ability of the laser to follow the data track in the disc. Light scratches and fingerprints are very common, and while they both can impede laser reading, their effects on the disc are somewhat different. Scratches affect discs differently depending on the side of the disc affected, the severity and direction of the scratch, and the type of disc.

5.2.1 Scratches on the Laser-Reading Side of CDs and DVDs

Scratches generally cross data lines or tracks on the disc, and how bad (deep and wide) they are will determine the extent of interference with laser focus on the data. Small or occasional scratches will likely have little or no effect on the ability of the laser to read the disc, because the data are far enough below the surface of the disc that the laser is focused beyond the scratch. This is comparable to the effect of a light scratch on a pair of eyeglasses; it does not markedly impair vision because the viewer’s eyes are focused beyond it.

Even assuming a scratch is deep or wide enough to influence laser focus, error detection and correction coding in the disc drive can in many cases recover the misread data. However, scratches that are deep, wide, or bunched together can adversely affect the readability of the disc. These scratches can cause the laser to misread enough data to make error correction coding ineffectual.

While data errors generated from scratches that run outward from the center of the disc stand a good chance of correction by the error correction firmware, scratches running in the direction of the track, the same direction as the laser reads the disc, are more likely to cause uncorrectable errors. These uncorrectable errors are called E32 in the Red Book for CD specifications, and PO Error in DVD specifications.

If scratches are deep enough to damage the data or metal layers on the reading side of a disc, the data cannot be read or repaired.

5.2.2 Scratches on the Label Side of CDs

Scratches on the label side of CDs can be a more serious problem. Because the reflective metal layer and data layer are so close to the surface of the label side of the disc, they can be damaged very easily. A slight indentation, or pinhole in the metal from a scratch, pen, pencil, ultrafine marker, or other sharp object will destroy the reflectivity of the metal in that area on the other side (laser reading side) and the readability of the data by the laser. This type of damage cannot be repaired.

As with scratches on the laser-reading side, optical disc drives are usually able to read through minor damage easily, even if the damage is caused from the label side. The difference is that this damage is permanent. If the error detection and correction firmware in the disc drive cannot correct the data, it will not be recoverable. Scratches that do not reach through the thin protective lacquer coating should have no immediate effect but may ultimately expose the metal to moisture, air pollutants, or other adverse environmental influences.

Adhesive labels (see page 23), though also somewhat vulnerable to adverse environmental influences, can provide CDs with extra protection from scratches. The extra layer on printable discs likewise offers protection.

5.2.3 Scratches on the Label Side of Single-Sided DVDs

Scratches on the label side of single-sided DVDs are not likely to pose a problem. The metal layer so prone to damage in CDs is in the middle of DVDs. Its location makes this layer almost impervious to surface scratches; it is in fact unlikely to be affected by any but the deepest scratches-those deep enough to reach the center of the disc where the metal and data lie.

5.2.4 Fingerprints, Smudges, Dirt, and Dust

Fingerprints, smudges, dirt, or dust on the laser reading side of the disc can disrupt laser focus on the data even more than a scratch can. Dirt or dust on the disc will block or reduce the light intensity of the laser. If severe enough, it will cause the disc drive to miss data as the disc is being read. Fingerprints, smudges, or dirt cover wide areas of data and will cause the laser beam to go out of focus or lose intensity. They will also cause widespread misreading of data along the data lines or tracks, to an extent that exceeds the error correction capability of the disc drive. Dust can also spin off into the disc drive and collect on the laser head or other internal components. Fingerprints, smudges, and dirt are easier to remove than scratches; it is simply a matter of cleaning them off.

To summarize, the effects of scratches versus fingerprints and smudges on the laser reading side of a disc include the following:

- Occasional fine scratches will typically not affect the focus of the laser.

- Deep scratches can affect the focus of the laser and cause errors.

- The error detection and correction coding system in the disc drive will correct many errors caused by scratches.

- Fingerprints and smudges can cause more errors than scratches and are more likely to overwhelm the error correction coding system capability.

- Scratches in the direction of the track (tangential direction) are worse than those going from the center of the disc outward (radial direction).

- Like fingerprints and smudges, several scratches close together can also overwhelm the error correction coding system capability.

5.2.5 Marking

Marking and labeling a CD or DVD is an essential process in its creation. CDs and DVDs, or their containers, are labeled in some form or fashion so that they can be identified and organized. When labeling a CD with markers, the composition of the ink in the marker and the style or design of the marker should be considered.

The inks in markers vary in chemical composition and are formed from pigments or dyes, and solvents. Inks are divided into three basic categories according to the type of solvent used: water-based, alcohol-based, and aromatic solvent-based. Within these categories, inks are further divided according to their permanence and their application to different surfaces.

Markers themselves also vary in form: there are fine-point, extra fine-point, rolling-ball, ballpoint, soft felt-tip, and chisel-tip. Some are ideal for CD labeling; others can cause damage.

Numerous CD vendors have noted that the thin protective lacquer coating can deteriorate from contact with certain solvents in markers. To eliminate the risk, water-based markers are recommended for CD labeling. As a solvent, alcohol is generally less damaging than xylene and toluene, which are common in aromatic solvent-based markers. According to anecdotal reports, alcohol-based markers can be used to label CDs without causing performance problems. However, there are no explicit lab test results to show what effect solvents in markers have on different CDs or DVDs, particularly over the long term.

The vulnerability of the metal in CDs, because of its proximity to the surface, should be considered when choosing a marker. The metal is particularly susceptible to damage from scratches, scrapes, or denting caused by surface marking. A felt tip marker will minimize the risk of scratching or denting.

As mentioned before, CDs and DVDs look similar, but their layer structures differ. The recording layer of a CD is located just beneath the labeling side. On a DVD, the recording layer is in the center of the disc. In theory, solvents from a solvent-based marker will not penetrate to the center of a DVD through the polycarbonate layer on both sides of the disc. Consequently, the data and metal layers in the center, in theory, should not come in contact with any harmful solvents. Nevertheless, the same precautions taken in labeling CDs are advisable for DVDs. The marker used to label a CD will work just as well on a DVD. Restricting oneself to the CD-safe marker will also eliminate the potential for mix-ups in the use of distinctive CD or DVD markers.

| Never use a fine point or rolling ball marker on a CD because it may scratch or depress the surface of the disc and permanently damage the metal and data layers. |

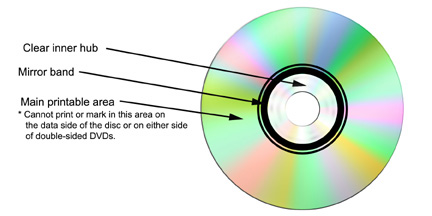

Many vendors sell CD-safe markers, and they vary in ink solution. They should not contain any solvents harmful to CDs or DVDs but should have a permanent quality. For risk-free labeling of any disc, it is best to mark the clear inner hub or the so-called mirror band of the disc, where there are no data (see Figure 12).

Figure 12. Printable or markable areas of the disc

5.2.6 Flexing

Flexing (bending) the disc by any means, such as removing it from a jewel case or sitting on it, may harm the disc by causing stresses. The disc should be stored in its case and placed vertically, like a book, on a shelf. Long-term horizontal storage, particularly in a heated environment, can cause the disc to become permanently bowed. While the data may still be intact, the disc may not operate properly in the drive or permit the laser to follow the track. The maximum degree of flex (bend) or number of times a disc can be flexed before it incurs damage is not known. To minimize the risk of damage, it is better to avoid flexing discs.

5.2.7 Application of Adhesive Labels

Adhesive labels should not be applied to optical discs destined for long-term storage (more than five years). The label could delaminate over time and interfere with disc drive operation. The adhesive in some earlier labels has also been known to react with the lacquer surface. Any attempts to peel the label off could cause damage to the lacquer and metal layers in CDs. DVDs are different; peeling a label off a DVD would not have the same adverse affect because the metal layer is not near the surface. Still, removing a label, or any portion thereof, from the surface of a disc can cause an imbalance in the spin of the disc in the disc drive, making the disc unreadable. DVDs are more susceptible to reading problems from minor imbalances than are CDs. To ensure the long-term availability of information on a disc that already has an adhesive label, the information on the disc should be copied to, and stored on, a disc without such a label.

Adhesive labels may be well suited for short-term disc usage (less than five years), and can even add a layer of protection from scratches and other potentially harmful contact. On the other hand, such labels are vulnerable to adverse environmental conditions: they can dry out or absorb moisture, and they can be affected by heat or cold even more than the disc itself. Such conditions may cause the label to delaminate. Disc manufacturers advise against using adhesive labels because they can create unbalanced disc spin, resulting in premature wear of the drive. If a label is used, it should be manufactured for use on CDs or DVDs, and an appropriate disc label applicator tool should be used to affix the label. The label applicator tool should center the label on the disc so as to maintain the disc balance as much as possible.

5.2.8 Disc Surface Printing

Printing labels directly on CD-R and DVD-R requires the use of discs to which a printable surface is added at time of manufacture. The following printing information relates mostly to CD-R discs, but would also apply to the DVD-R versions.

Inkjet printing and thermal transfer printing are commonly used for labeling the surfaces of CD-R discs. Each involves a different technology to place inks on the printing surface of the disc; few inkjet-printable and thermal printable CD-Rs are interchangeable.

The printable area on a DVD disc depends on whether the disc is single- or double-sided. A label may be printed on the top side of a single-sided DVD, much like on a CD. However, the performance of a DVD is more sensitive than that of a CD to any imbalance of the disk. Because ink affects the flatness and balance of a disc, full surface printing may not be the best choice since the ink may not be uniformly distributed over the disc surface. Nonetheless, if you choose to print labels on your discs, full surface printing is better than partial surface printing. For full surface printing of either a CD or a DVD, a white, printable base coat is available.

“Pit art” labeling, as an alternative to printing, avoids the flatness and balance issues. The pits are produced on the label side (without having a printable surface), creating a mirrored, holograph-like pattern on the metal layer that becomes the label. Because no ink is used, the flatness and balance of the disc are not compromised.

If a DVD disc has data on both sides (double-sided), neither printing nor pit art may be used in the data area of the disc. Only the area of the mirror band and the area between the mirror band and center hole may be printed on or marked.

Thermal Printing

In thermal transfer printers, a print head that contains resistive elements in a linear array heats ink-coated films (ribbons). The head is in direct contact with the uncoated side of the ribbon, and the ink-coated side of the ribbon is in direct contact with the disc’s printable surface. The ink is heated, causing it to melt and adhere to the printing surface. Specially formulated materials are used for the printable surface of the disc to enhance ink transfer efficiency and adhesion. Only specially designed thermal printers-not thermal printers designed to print on paper-can be used to print directly on the surface of thermal printable CD-R discs.

Inkjet Printing

In inkjet printers, inks are sprayed, via droplets of an ink solution, onto a specially designed printable surface material on the disc. This surface is designed to hold the ink droplets in place while absorbing the liquid components of the ink.

Silkscreening

Silk screening on CDs or DVDs uses a UV-curable ink to keep the ink colors from running together. That ink cannot contain any chemically active components that can affect the disc after the curing process or abrasive particles in the ink pigments that can damage the protective layer of CDs.

5.3 Wear from Disc Play

CDs and DVDs do not wear from friction as vinyl records or tapes do. There is no physical contact with the disc in the area that the laser uses.

ROM Discs: The laser light will have no effect on the data or metal layer in ROM discs. In theory, it is possible for the disc to be read so many times that the cumulative effect of the laser light can eventually affect the polycarbonate. There is, however, no record of such discs having been played a sufficient number of times to incur damage from laser light. Accordingly, it is felt that any effects of the light on ROM discs is negligible. It is assumed, in fact, that the disc would likely fail much earlier from some other condition than from the effects of laser light.

R discs: In theory, R discs should have a limited number of read times (several thousand) because of the cumulative effect on the data layer from the laser light. As with ROM discs, the polycarbonate may also eventually be affected, but there is no recorded evidence of ill effects of laser light, so such effects are deemed negligible.

RW discs: RW discs, unlike the other types, can “wear-out.” CD-RW and DVD-RW discs should last for about 1,000 rewrites, and DVD-RAM discs, 100,000 times, before the rewriting capability is lost. The reading functionality of the disc should continue for a limited number of read times after each writing. While the maximum number of read times possible after writing is unknown, it may become fewer after each successive writing.